Hospitals Saving Lives and Money With Steril-Aire

Steril-Aire at Auckland Airport

High-output UVC EmittersTM reduce energy expenditures even as an airport expands.

Becoming a major gateway to green. That’s precisely what New Zealand’s Auckland airport’s newly remodeled international passenger terminal was tasked with in 2007. New Zealand’s largest commercial building, handling 13 million passenger movements per year, had a goal to reduce their carbon footprint by 5% before 2012.

This was a seemingly Herculean effort, because the terminal was also to be soon taking on more retail space while increasing passenger numbers by 4.9%. More people consuming, but less energy expended? How would that be possible? Enter Superior Air-Solutions, with the unsurpassed Steril-Aire UVC coil-cleaning and air contamination control EmittersTM installed in the HVAC system. According to Martin Fryer, the airport’s Sustainability Advisor, these were a major part of the solution. Mr. Fryer states “This was a real win-win-win for Auckland Airport – reduced energy costs, reduced carbon footprint and improved air quality for our passengers and tenants.”

Although they wanted to reduce their carbon footprint by 5% by 2012, they actually achieved that goal 2 years ahead of schedule, and much of that success was directly linked to the decrease in energy expenditure of their HVAC systems.

(Reduced carbon dioxide emission goals were achieved 2 years ahead of schedule.)

Savings are in the air (conditioning system).

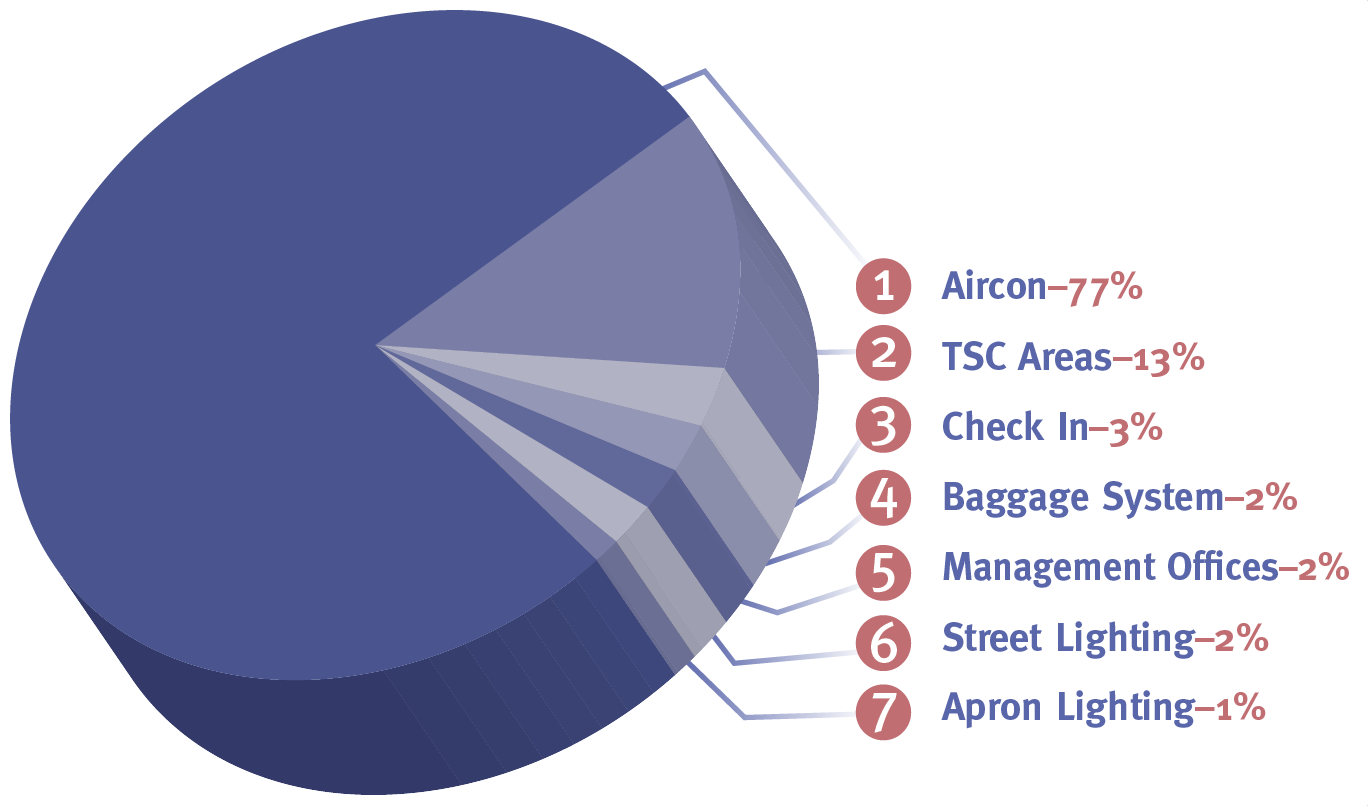

An audit done by Auckland Airport showed that 77% of electrical energy use was related to air conditioning showing that the efficiency of the HVAC units is critical to energy savings. This efficiency is extremely hampered by biofilm that builds up on the cooling exchange plates, inhibiting the heat transfer process and reducing airflow.

By destroying the biofilm, Steril-Aire’s high-output Emitters eliminate the need for manual coil cleaning and chemical usage. Coils, drain pans and plenums stay free of mold and bacteria – restoring equipment to their original performances without using harmful toxins or requiring expensive maintenance.

(An energy audit revealed that HVAC energy use accounted for 77% of the overall building electrical usage. Steril-Aire UVC helped substantially improve performance while reducing energy and maintenance costs.)

Steril-Aire’s patented installation downstream of the coil is critical for best results.

High-output UVC emitters mounted downstream from the coil destroy mold, bacteria, viruses and VOCs preventing them from re-entering the air.

$272,000 savings each year!

Keeping biofilm from the coils in over 100 air-handling units has resulted in a return on investment in merely 1.5 years, according to Martin Fryer. This is well under their ambitious time-frame goal. And all the while, there was no disruption of service and no passenger interruption.

“We reduced our carbon footprint by just over 400 tons” said Fryer, “because Steril-Aire produces the highest output UVC Emitters available.” The overall cost savings are a verified $272,000 each year and a 2,480MWh reduction each year. That’s an incredible reduction of 2,480,000 kWh.

(Biofilm buildup greatly increases energy consumption in HVAC systems.)

Breathe better benefits

Over one billion passengers per year travel by air. Airports and airplanes are all confined spaces with predominantly recycled air. One person breathes out. Another person breathes in. What is that other person breathing in? Airborne viruses. Bacteria. And more.

Steril-Aire’s high output germicidal UVC has been shown to be very effective in reducing surface and airborne mold, bacteria and viruses. Microbial testing at Auckland International Airport showed a greater than 99% reduction in mold and bacterial colonies forming in units 31 days after installing Steril-Aire Emitters.

Microbial testing shows remarkable improvement after 31 days

Summing-up Steril-Aire savings

• Reduction in mandatory carbon footprint well ahead of schedule

• Reduction in energy costs of $272,000 per year

• Reduction in carbon emissions

• Reduction in AHU microbial load, resulting in improved indoor air quality

• Reduction in costs of HVAC maintenance

• ROI of less than 18 months

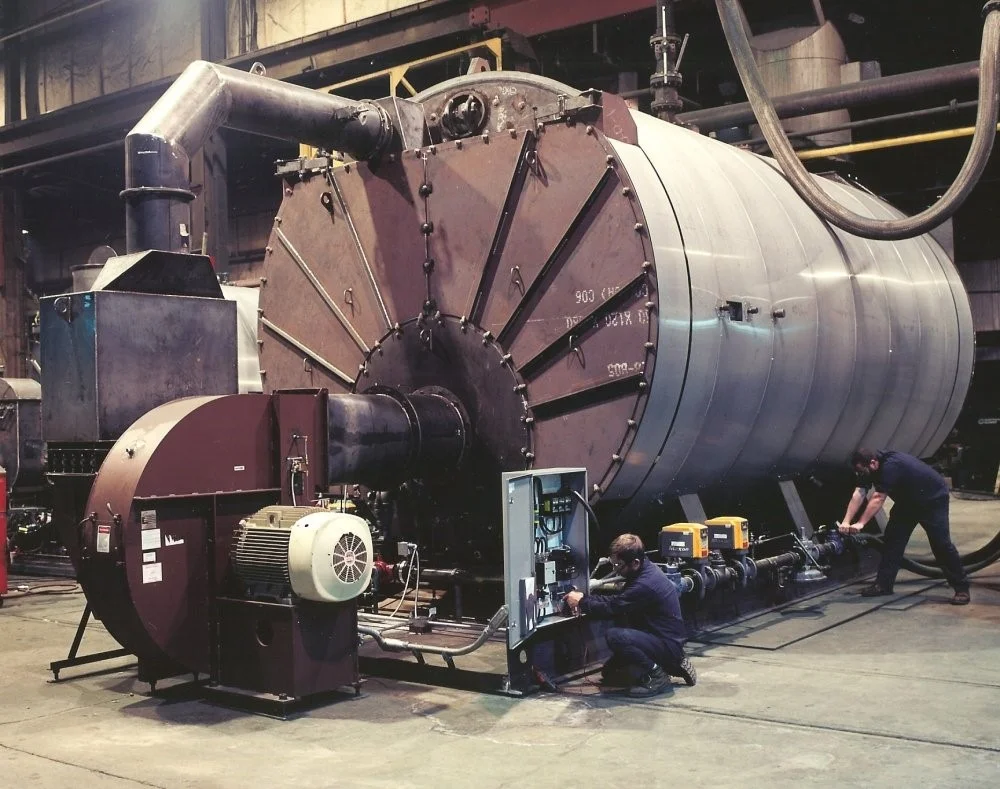

Boiler Protection in Dairy Sector

Reducing the risk of unexpected downtime is crucial for one of New Zealand’s leading dairy producers. Therefore equipment such as boilers need to be protected from corrosion when not in use. Accordingly, Air Solutions have supplied Fisair desiccant dehumidifiers to control humidity levels inside of power generating boilers.

Providing a Low Humidity Environment for Transformer Repair

Our client was required to carry out maintenance on specialised transformers. To complete this maintenance work, a temperature specific, very low humidity environment was required to maintain the integrity of the transformers.

Equipment such as transformers need to be kept in a low humidity environment for any repairs and maintenance. Accordingly, Air Solutions sister company in Australia have supplied desiccant dehumidifiers to control humidity levels inside of purpose built maintenance buildings.