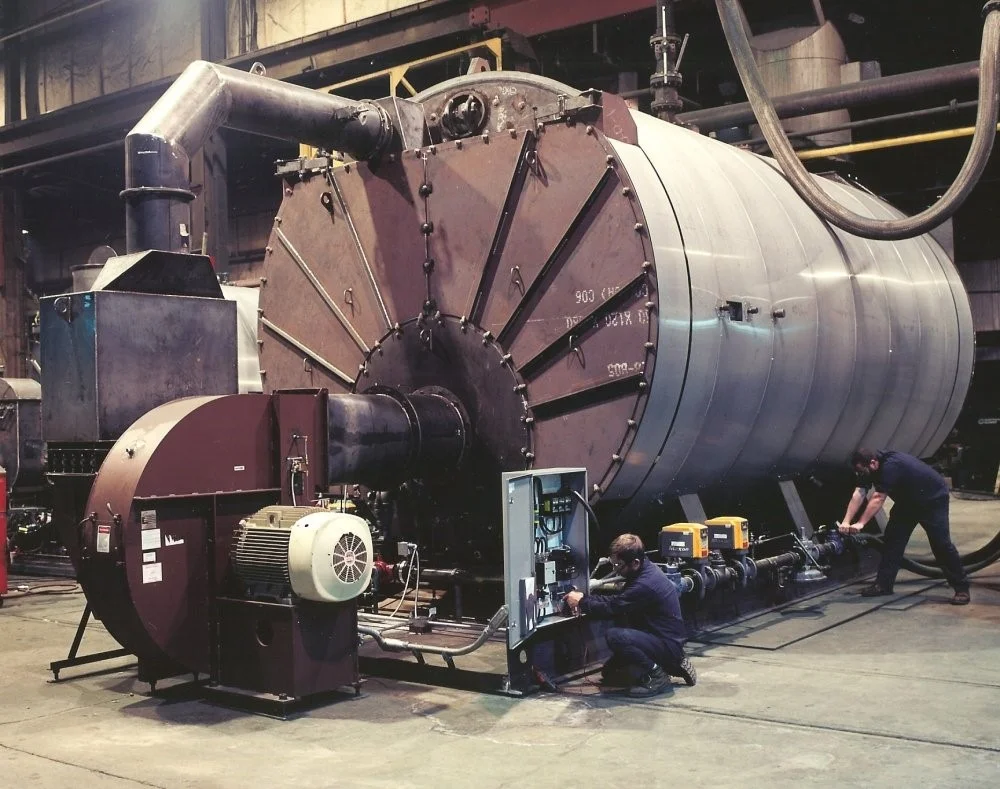

During stopages, turbines tackle very severe corrosion risks. If appropriate measures are not taken, corrosion can cause a lot of damage to many different system components, and can result in major disruptions to the restart. Find out how Air Solutions can help with temporary rental dehumidifiers.